The fact that you are leafing through this booklet shows that you are a smart entrepreneur! Thank you for contemplating Green Block for your varied construction needs.

In today’s competitive, tough economic climate, every business or construction company is compelled to optimize costs without compromising on quality, efficiency and speed in their projects. Towards this end, Green Block turns out to be the best material of choice endowed with many superlative properties. It is an economical, eco-friendly, reliable and long-lasting option that adds value to the construction in several ways.

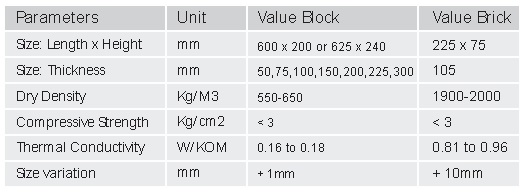

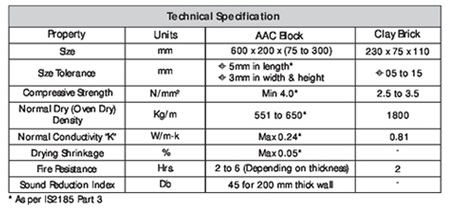

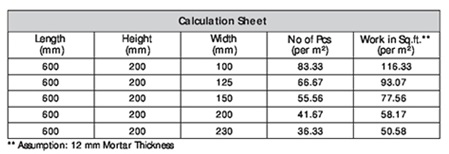

Green Block is available in multiple configurations of dimensions, thickness and strength. Kindly review the Technical Chart to select the best option for your construction activity.

Just in case you need any assistance, our friendly experts are available to guide you with your selection.

The passion to excel, The vision to lead, and The desire to make a positive difference…

The KD Group of Industries prides to be a major enterprise in the North Eastern region of India. It is a growing conglomerate with a deep footprint in the Cement, Steel, Metallurgical Coke and Real Estate verticals.

The Group aims to be at the leading edge of growth in the NE region; it is a consortium backed by state-of-the-art production units, a strong dealer network and a loyal customer base.

Leveraging our extensive expertise in the building material industry, the Group has launched a new line of Autoclaved Aerated Blocks (AAC) by the brand name Green Block.

The launch of Green Block symbolizes a positive step in the direction of sustainable development. By bringing this brand into the market, we seek to give a boost to eco-sensitive, green construction practices.

Mr. Dilip Goenka is the pioneer in introducing AAC blocks to North- East India. He co-founded Briko-lite & Green AAC block and currently is the Managing Director of Green AAC block. He is an Industrial Engineer by education . As a serial entrepreneur, he has conceptualized and started many successful projects in North-East some of which include : KD Iron (xtech), BR Metallics ( Green AAC) and international projects in Bhutan ( Druk Metallurgy).

Mr. B.K. Goenka is a law graduate and looks after the day to day office functions of the group companies which include Sales, Purchase, Accounts, legal, Finance and Fund planning functions. As a serial entrepreneur, he has been instrumental in setting up successful companies in North-East some of which include : KD Iron (xtech), BR Metallics ( Green AAC) and international projects in Bhutan ( Druk Metallurgy).

Mr. Hanuman Jain is one of the Partners at the company and currently looks after Green AAC’s business in the lower North-East . He is a commerce graduate and founder of the M/S Steel Traders. He has over 45 years of managerial and channel marketing market experience, Mr. Hanuman Jain has been instrumental and winning a lot of market segments for its associated manufacturers.

Harsh Jain is one of the Partners at the company and currently looks after Green AAC’s business in the lower North-East . He has over 8 years of work experience in the construction industry. He is the founder of India’s first interior design marketplace,Nestopia. He looks after the day-to-day operations of Silchar Plant. He is a Bachelors in Finance from Rutgers Business School, USA.

Make buildings eco-friendly, cost-effective and sustainable

Be the leading wall solution company in the North-East by providing superior products at great value.

Persistence & embracing failure | Progress not at other's expenses.

Accountability: |Reputation over quick profits.

Courage: to Dream Big.

Integrity: to be honest to self and others.

Learning & Continuous Improvement.

AAC Block is produced from inorganic materials – lime, sand, cement and water and offers multiple benefits over conventional building materials. To list out only a few advantages, it has excellent thermal and acoustic insulation and great workability.

Autoclaved Aerated Concrete (AAC) is a lightweight, precast building material that simultaneously provides structure, insulation, and fire- and mold-resistance. AAC products include blocks, wall panels, floor and roof panels, cladding (facade) panels and lintels.

It is indeed interesting to understand AAC Blocks from a historical perspective.

AAC was perfected in the mid-1920s by the Swedish architect Dr. Johan Axel Eriksson, working with Professor Henrik Kreüger at the Royal Institute of Technology. Eriksson was searching for material with the properties of wood – good thermal insulation, solid structure, easy to work with & handle – but without the disadvantages of combustibility, decay and termite damage. After much experimenting, Eriksson succeeded in developing AAC, which went into commercial production in a factory in Sweden in 1929 and gained popularity over the decades.

Today, AAC is manufactured by about 1000 plants in 35 countries and is extensively used in residential, commercial and industrial construction for more than 70 years.

Enables soil conservation, reduces pollution, optimizes logistic cost and effectively increases carpet area.

Saves fertile land:

Fly ash waste generated in thermal power plants is used in making Green AAC Block. Unlike red brick manufacturing, it does not require fertile clay; it thus helps in conserving soil and safeguarding the environment.

Also, we dig up sand from the Brahmaputra River and use it in the manufacturing of AAC Block. Due to this the depth of the River increases and it stays its course, preventing from spilling over and causing floods in adjoining areas.

Recycling fly ash waste:

After hydro power, we are still largely dependent on thermal power, which presents a huge challenge of effectively disposing fly ash waste, which is precisely the major raw material for AAC Blocks.

Energy efficient- reduces carbon emission:

The manufacturing of Green AAC Block is a highly energy efficient process compared to the production of other walling material, which again helps to reduce carbon emission.

Saves fuel for transportation – lowers transportation cost:

Green AAC Blocks being lightweight, more volume of walling material (almost 3 times higher) can be transported in the same carrier, thus saving fuel for transportation by a staggering 66%.

Green Building Certificates:

Because of the above social and environmental benefits, it is the material of choice for green building certifying organizations such as LEED, IGBC, BREEAM, DGNB, CASBEE, etc.

Green AAC Block has state-of-the-art manufacturing facilities at Rangia (Guwahati) & Silchar, both on the National Highy 27 East- West Corridor . The plants are also within the 250km radius of most urbanized regions of north east India like Guwahati, Agartala, Imphal, Mizoram, Itanagaer, Silchar, Jorhat, Nagaon etc

Also, we dig up sand from the Brahmaputra River and use it in the manufacturing of AAC Block. Due to this the depth of the River increases and it stays its course, preventing from spilling over and causing floods in adjoining areas.

Our total installed capacity is 300,000 CBM/annum equivalent.

We constantly strive to provide better products to our customers, each of our manufacturing facility houses laboratory to test the quality of raw materials and finished products. Every batch of finished product is tested before dispatch.

Manufacturing Locations

Style, speed, convenience and cost control

Workability

Green Block units can be handled with greater ease and comfort, making them more convenient than regular clay bricks.

Speedy construction:

Green Block units enable rapid construction owing to their large size, fewer joints, hassle-free handling and easy manipulation (such as cutting & sawing).

Due to reduced turnaround time, construction companies can take up and complete more projects, resulting in improved business.

Due to reduced turnaround time, construction companies can take up and complete more projects, resulting in improved business.

Higher carpet area:

Attributes of Green Block such as high dimensional accuracy and reduced plaster thickness result in an increase of 2% carpet area.

Greater material efficiency:

Being lightweight than conventional clay bricks, Green Block significantly lowers the dead weight of the structure by 50%, which leads to lesser consumption of cement & steel (15 t0 20%).

Quicker application of finishes:

Since AAC compatible finishes can usually be directly applied with spray equipment in a one-coat application, the time associated with finishing the building is minimized. Many products can also be specified with integral colour, eliminating the costs and time associated with painting.

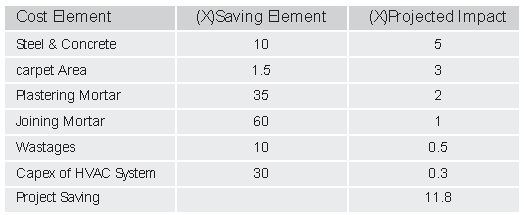

Substantial cost savings:

Green Block results in cost-optimized, high quality construction due to:

1. Lower Logistics Costs:

Due to the low weight of ACC products, the capacity for transporting the material is maximized and related freight costs reduced.

2. Quicker Construction

The large size of the block allows much higher productivity than most materials. Construction crews can complete their work and move to the next project.

3. Reduce Finish Material Costs

Because of the fire, thermal, acoustic, and surface properties, finish materials such as insulation are not needed, Smaller AC Systems are usually possible when using AAC material.

4. Quicker Application of Finishes

Since AAC compatible finishes can usually be directly applied with spray equipment in a one-coat application, the time associated with finishing the building is minimized. Many products can also be specified with integral color, eliminating the costs and time associated with painting.

5. Lower Life cycle Cost

The durability of the AAC Block minimizes ongoing maintenance and repair costs normally associated with conventional construction.

6. Lesser structural steel requirement

Due to light weight and low density, overall dead load reduces, thus saving structural steel consumption compared to conventional masonry.

7. Reduced mortar Use/Low Cement Consumption

This sheet is part of a series highlighting alternative design details which use less materials or result in less waste being created than 'standard' details used in construction. The benefits provided by the alternative design detail are quantified, and technical considerations presented.

70% lighter than standard concrete blocks

• Up to 80% less mortar – sets within 20 minutes.

• Construction times can be equivalent to off site methods.

• Modest extra cost of materials is off set by low waste and waste disposal.

• 21% less embodied carbon than standard blocks of the same size.

8. Reduce Internal Plaster Cost

AAC blocks are factory finished with precise edges & shapes, this result in economical POP or Putty finish and much reduced plaster cost.

9. Enhanced Labor Output

If you are using the AAC blocks for construction then you can make your home within a short time. These blocks can reduce the project time to almost 40%, and you can save the labor cost in the same way.

Energy conservation – higher energy efficiency & lesser carbon emission:

AAC Block has excellent thermal insulation and thermal storage capacity. These properties reduce energy requirement for both heating and cooling. In locations where off-peak energy rates are high, the thermal mass characteristics allow more of the air conditioning load to take place in lower cost periods of the day. It is fire and pest resistant, while still being environmentally responsible – real peace of mind for your customers and you.

Maintenance & Operations:

AAC material is inorganic and resistant to insect damage or infiltration. Since AAC is a solid material, there are no voids in the construction that present an opportunity for insects and pest inhabitation. Hence costs for pest control & treatment can be substantially reduced, if not eliminated.